Truck brake failure seldom happens due to a mechanical fault but negligence by the driver or truck owner. This can be clearly shown by examining what causes the truck’s brakes to fail.

Recently, a truck was filmed speeding uncontrollably down the N3 at Townhill eventually crashing into two other trucks. Smoke could be seen coming from the truck’s wheels which meant that the brakes were no longer effective which brings us to look into brake failure meaning, causes, and contributing factors.

What is a truck brake failure?

Truck brake failure is the malfunction of a truck’s brake system causing it to fail to operate effectively as it’s designed to. Brake failure can cause a vehicle to fail to stop in time or swerve from its path when brakes are applied causing a serious crash.

Truck brake system components and their purposes

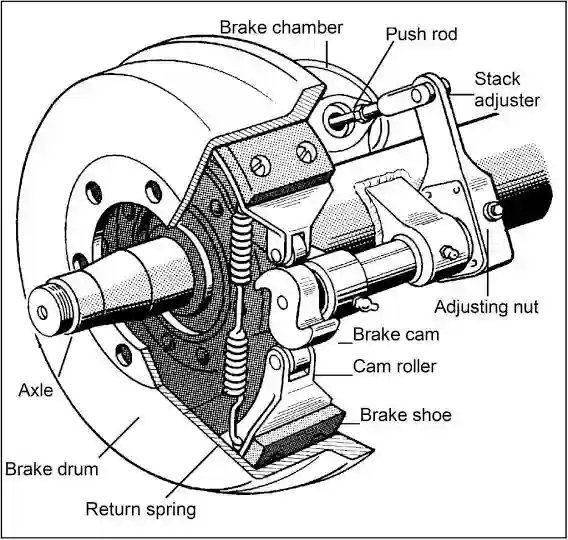

Truck brakes essentially consist of TWO systems as explained on Arrive Alive: Park (or Spring) brakes and Service (or Foot) brakes. The truck brake system has a cylinder that contains a strong spring and a vacuum chamber (booster). This is connected to a push-rod which is, in turn, connected to an arm (slack adjuster) which twists a shaft with a cam (S-Cam on it). The S-Cam causes two brake SHOES to expand (open up) and contact with the inside of a brake drum.

So, a truck brake system would be permanently ENGAGED if there was no external influence. A truck brake system works with a vacuum. If there is NO VACUUM, the springs would actuate the push-rod, which will lever the slack adjuster, turning the S-cam (shaft), engaging the brakes. When vacuum is applied, the push-rod (end) is “sucked back” and then the brakes are released. Then – every time a driver tries to “break” the vacuum would be released and the brakes would be applied. You can “essentially,” say that the truck brake system (air brakes) work in “reverse” to car brakes.

How Truck Air Brakes Work

Air brakes on trucks work using compressed air instead of hydraulic fluid as in cars. Air brakes can be either drum brakes or disc brakes, or a combination of both.

An air compressor mounted onto the engine, pumps pressurised air into storage tanks where it’s kept compressed until it’s needed.

The stored pressurised air serves two purposes on the truck’s brake system, applying the service brakes and releasing the parking brake.

When the air pressure in the chamber is released, the parking brake engages by means of spring force in the parking brake portion of the spring brake chamber.

Even if the air pressure drops too low, the force exerted by the spring in the chamber will be able to overcome the force exerted by the air on the diaphragm and apply the brakes on all wheels which means that the parking brake can also be used as the emergency brake system.

Trucks have two pressure pipes, one for the park brake (usually a red pipe) and service brake (usually a yellow pipe). The red pipe only releases pressure when applying or releasing the handbrake while the service line constantly supplies pressure to the trailer.

Reasons for truck brake failure

Truck brake failure does not usually happen in an instant, it happens as a result of lack of maintenance. Sticky calipers, oil contamination of components, leaky fluid lines, leaking pressure lines, and other mechanical issues can build up fast and lead to a brake failure. Ignoring early warnings of faulty braking system components eventually leads to brake failure. These are the main causes of truck brake failure:

Brake imbalance

Imbalance in your truck’s braking system is when one or more brakes are exerting more or less force than the others. This happens when you have mismatched parts, malaligned brake linings or an error in the pneumatic system applying air pressure unevenly. Brake imbalance is one the most common causes of truck jackknife accidents.

Brake overheating

The top culprit for overheating brakes is drivers when they apply poor braking techniques while driving downhill. Instead of downshifting to an appropriate gear some drivers use high gears forcing them to apply foot brakes to control their speed. This causes brakes to overheat rendering them inefficient when you apply them with the intention to stop the vehicle. Overheating can also be caused by imbalanced brakes, in this case a few axles may be affected causing the vehicle to not stop when it’s desired to.

Faulty suspension

A misconfigured suspension system can wreak havoc on your brakes by causing similar issues to brake imbalance. Softening your suspension could reduce stress on brakes and also result in a smoother driving experience on the road.

Trailer overload

Even the best kept, newest brakes on a truck cannot withstand excessively heavy loads. The breaking distance required becomes far too great, resulting in unnecessary on your braking system. Even one trailer overload is enough to cause brake failure. Don’t risk endangering the public highways for a load larger than your truck can handle. Unbalanced loads can also lead to brake failure, a load sitting at the back of a 12m flat deck trailer may lift the weight off the truck diffs rendereing brakes ineffective as there won’t be any traction.

Lubrication

Inadequate lubrication of your caliper pins, clips, mounting tabs, and brake back sides can make your brakes wear much sooner than expected.

Leaking air pressure lines

Leaking pressure lines means not enough pressure to the brake chamber or booster rendering them useless. If it takes too long to fill up your pressure gauges that may be a sign that you have a pressure leak. another sign that you may have a pressure leak is when you notice a sudden drop of pressure when you apply foot brakes. In case of an emergency, you may not be able to stop in time because of this.

Truck maintenance is ongoing

Faulty brakes don’t happen overnight. It’s often due to an oversight on the part of the driver or fleet manager. Make truck maintenance a regular procedure so that you are always safe from potentially disastrous crashes. Fleet managers can take the initiative as well, by implementing a more robust fleet safety program. Truckers are advised to note down and report any brake faults and make sure they are ficed before getting onto the road.